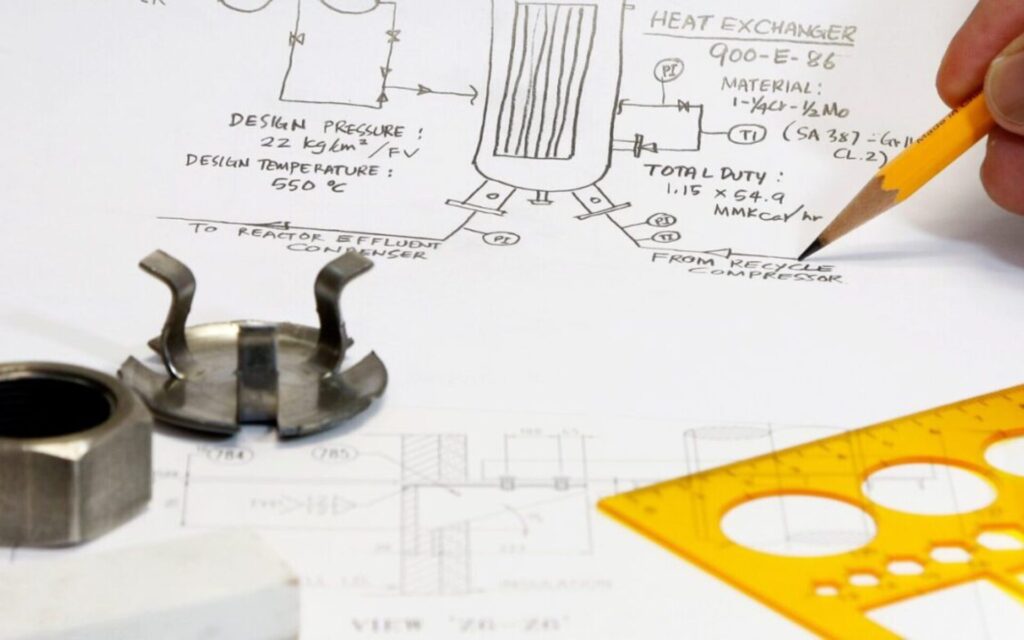

Innovation brings new risks along with new opportunities. Our systematic hazard analysis identifies and mitigates safety risks before they become problems, ensuring your pilot plant operates safely while maintaining the flexibility needed for process development.

Our HAZOP methodology: We use industry-standard HAZOP methodology adapted for the unique challenges of pilot plants and demonstration facilities. Our approach balances rigorous safety assessment with the operational flexibility essential for process development. We can also perform other types of Process Hazard Analysis (PHA) depending on need, from lightweight What-If to comprehensive LOPA analysis.

Software Tools: We use PHAWorks (industry-leading PHA software) for all PHA studies ensuring professional documentation and efficient study execution. PHAWorks provides: – Standardized HAZOP worksheets and formatting – Built-in libraries of guide words and consequences – Automated action item tracking and follow-up management – Professional reporting suitable for regulatory submissions

Study Leadership Experience: Our HAZOP facilitators have led studies for processes involving: – Hydrogen production and handling systems – High-pressure and high-temperature operations – Toxic and corrosive chemical handling – Electrochemical systems with AC and DC power hazards – Innovative processes with limited operating experience

Typical HAZOP timeline: 2 week lead time for preparation, 3-5 days for workshop sessions, and 1 week for follow-up and reporting

Technical oversight and advocacy needed to ensure successful project outcomes.

Professional documentation needed for equipment procurement, construction, and operation.